Features, Facts & Benefits

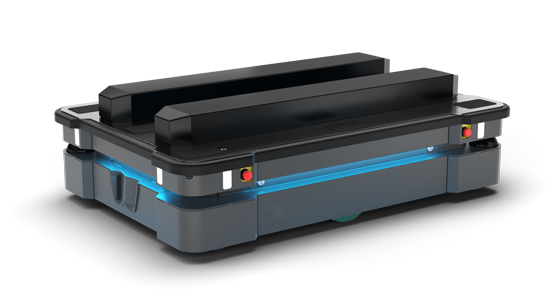

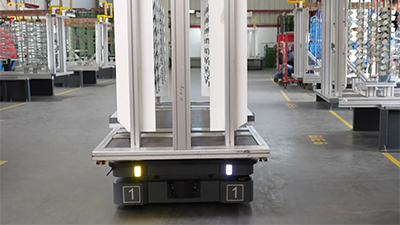

Agile

• Suitable for most environments

• Navigability in highly dynamic settings,

confined spaces, over ramps, in elevators

Collaborative & safe

• Safe collaboration with humans

• Avoidance of static & moving

obstacles

• Meets relevant safety standards

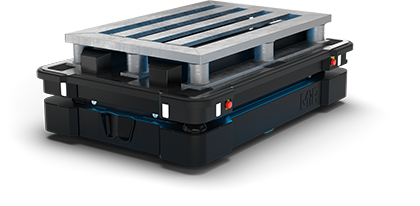

Flexible

• No operational modifications required

• No infrastructure required for equipment navigation

• Easy adaptation of AMR setup due to

process changes

• Individual solutions with MiR add-on modules

Easy to operate

• Easy setup & fast deployment

• Complete software included, no additional

IT infrastructure required

• User-oriented, simple programming

System integrable

• Can be integrated into your ERP / WMS

Scalable

• Simple, central configuration of an AMR fleet

• Harmonized AMR coordination for efficient

traffic flow

• Fast integration of additional AMR via MiR Fleet

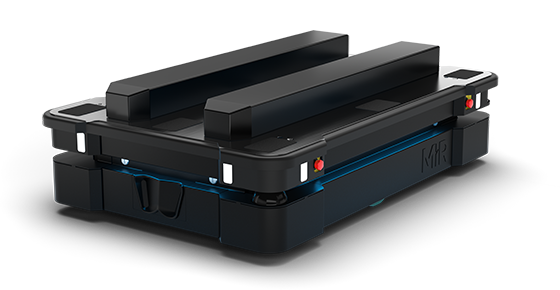

Economical & efficient

• Higher productivity through optimization of internal

goods / pallet transports / personnel flexibility

• Selection of the shortest route, if necessary,

automatic alternative route calculation

• Multiple stations possible during 1 mission

• Bottleneck avoidance in intralogistics

material flow