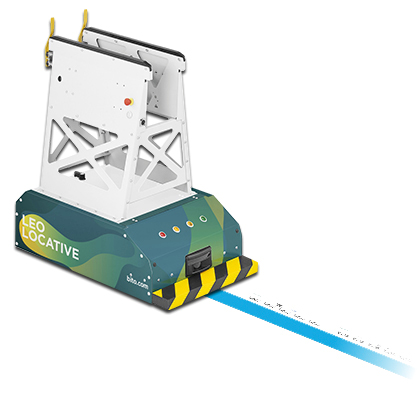

Design / Concept

Decentrally controlled, optically track-guided automated vehicle system for internal transports of light totes & cardboard boxes in the logistics & production area

| Head-Banner Landing Kleintransporte |

| Text Einleitung Landing Kleintransporte |

MOBILE ROBOTS has the solution for your internal small parts and SLC transport. Safe, contactless, resource-saving. Rely on our single or networked automated guided vehicle systems with payloads from 20 to 260 kg and towing loads up to 500 kg.

Below you will find an overview of our track-guided small parts transporters and AMR platforms for small to medium payloads. For each robot model, we provide detailed information* on the corresponding product pages.

* Correspond to manufacturer's specifications; subject to change & errors excepted.

| Bild BITO Spalte KLT |

| Name BITO Steckbrief |

| Daten-Akkordeon BITO KLT |

Decentrally controlled, optically track-guided automated vehicle system for internal transports of light totes & cardboard boxes in the logistics & production area Max. load capacity: 830 x 500 x 921 mm (LxWxH) 2.5 km/h (0.7 m/s) Accumulator Track tape / • Entry-level device for theDesign / Concept

Payload

20 kgDimensions & Weight

42 kgAccuracy

Max. Speed

Power Supply

6 - 8 hrs. charging time

(battery charger)Safety & Protection

Communication

Ground markingsKey Facts

simplest tasks

• Easy & autonomous

set-up

• Simple commissioning

• Fast adaptations

• Arbitrary scalability

• Goods distribution to over

500 destinations

• Short payback time

| Button > BITO |

| Bild MiR100 Spalte |

| Name MiR100 Steckbrief |

| Daten-Akkordeon MiR KLT 100 |

Freely programmable autonomous mobile robot for smaller internal transport tasks in production, logistics & healthcare; optional superstructures possible Max. load capacity: 890 x 580 x 352 mm (LxWxH) 5.4 km/h (1.5 m/s) Integrated battery management system WIFI • Increases operational safetyDesign / Concept

Suitable for collaborative use in environments with people and contactless operationPayload

100 kg (at max. 5% incline)

Max. tensile load

for trailer module MiR Hook:

300 kg (at max. 1% incline)Dimensions & Weight

Ground clearance: 50 mm

70 kgAccuracy

+/- 10 mm to docking markMax. Speed

Power Supply

Li-NMC, 24 V, 40 Ah

(Lithium-ion accumulator)

120 min. charging time

(0 - 80%, station)Safety & Protection

3D camera Intel RealSense for detection of objects in the travel path 50 - 1,800 mm above the floor

4x ultrasonic sensors

Acoustic & visual signalingCommunication

Input/Output: USB & Ethernet

Bluetooth 4.0 LE,

Range: 10 - 20 m

Fleet-ready

Can be fully integrated with your existing ERP / WMSKey Facts

• Navigability in confined spaces

& highly dynamic settings

• High customizability for

various applications

• User programmable

• Automatic battery charging

• WIFI Communication

• Permanent status insight

| Button > MiR KLT |

| Bild MiR250 Spalte |

| Name MiR250 Steckbrief |

| Daten-Akkordeon MiR KLT 250 |

Freely programmable autonomous mobile robot for internal transport & logistics tasks in production & logistics; optional superstructures available Max. load capacity: 800 x 580 x 300 mm (LxWxH) For VL markings position robot center: 7.2 km/h (2.0 m/s) Integrated battery management system SICK safety laser scanner WIFI • Increases operational safetyDesign / Concept

Suitable for collaborative use in environments with people and contactless operationPayload

250 kgDimensions & Weight

Ground clearance: 25 - 28 mm

83 kgAccuracy

+/- 5 mm (angle +/- 1°)Max. Speed

Power Supply

Li-NMC, 48 V, 36Ah

(Lithium-ion accumulator)

60 Min. charging time

(0 - 80%, station)Safety & Protection

(front/rear) for optical 360° protection

2x 3D camera Intel RealSense D435 for detection of objects in the travel path up to a height of 1,800 mm at a distance of 1,200 mm, 114° horizontal view

8x Proximity sensors

Acoustic & visual signalingCommunication

Inputs/outputs: 4x digital each,

1x Ethernet connection,

1x connection for ext. emergency stop

Fleet-ready

Can be fully integrated with your existing ERP / WMSKey Facts

• Navigability in confined spaces

& highly dynamic settings

• High customizability for

various applications

• User programmable

• Automatic battery charging

• WIFI communication

• Permanent status insight

| Button > MiR KLT 2 |

| Call-to FTS bottom |

Make an appointment now to plan your autonomous intralogistics with mR MOBILE ROBOTS and let us talk about a customized integration of

Automated Guided Vehicle systems (AGV) / Autonomous Mobile Robots (AMR)

in your company.