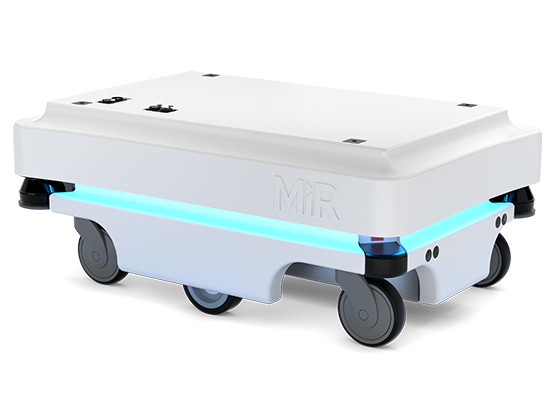

Application & Cargo

Autonomous mobile robot for small transport tasks in production, logistics & healthcare; suitable for collaborative use with humans in (highly) dynamic environments (indoor)

Loading area for individual setup:

890 x 580 mm (LxW)

Protection class: IP20

Payload

Max. load capacity:

100 kg (at max. 5% incline)

Max. tensile load

for trailer module MiR Hook 100:

300 kg (at max. 1% incline)

Dimensions & Empty Weight

890 x 580 x 352 mm (LxWxH)

Ground clearance: 50 mm

70 kg

Max. Speed

Forwards: 5.4 km/h (1.5 m/s)

Backwards: 1.0 km/h (0.3 m/s)

Travel Path, Track Width & Floor

Minimum corridor width: 1,000 mm

Surmountable tolerance gaps & thresholds:

20 mm

Small water puddles can be passed through.

Position Accuracy & Turning Radius

+/- 50 mm to postion

+/- 10 mm to docking mark

Turning: 520 mm (around robot center)

Turning diameter at obstacle/wall

with normal space requirement:

1,300 mm

Turning diameter at obstacle/wall

with minimized space requirement:

1,200 mm (no load) / 1,100 mm (full load)

Power Supply, Charging & Range

Accumulator: Li-NMC, 24V, 40Ah

Charging time (cable):

approx. 4.5 hrs. (0 - 80%: 3 hrs.)

Charging time (station):

approx. 3 hrs. (0 - 80%: 2 hrs.)

Input voltage: 100 - 230V ac, 50 - 60 Hz

Output voltage: 24V, max. 15A

Range: 10 hrs. or 20 km,

depending on load conditions

Certifications & Approvals

Certified for clean rooms

Safety standards:

CE, EN1525, ANSI B56.5, ISO13849-1, EN61000-6-2 & EN61.000-6-4

Safety

SICK safety laser scanner S300

(front/rear) for optical 360° protection

3D camera Intel RealSense for detection of

objects in the travel path 50 - 1,800 mm above the floor

4x ultrasonic sensors

Acoustic & visual signaling

Communication

WIFI dual band, wireless, AC/G/N/B

Input/Output: USB & Ethernet

Bluetooth 4.0 LE, Range: 10 - 20 m