Modular production logistics: The VARIO MOVE transport robot series

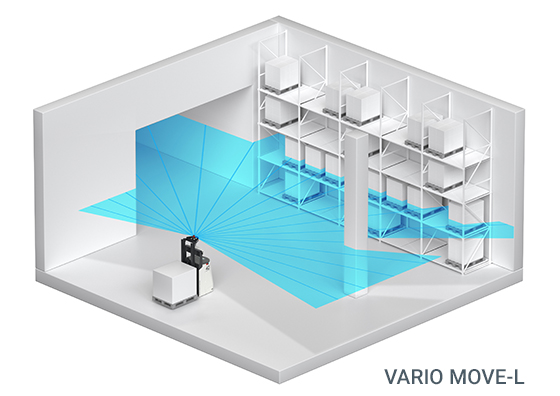

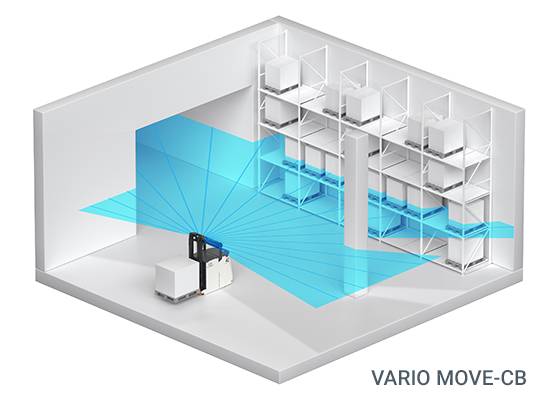

Short planning and commissioning times, fast delivery and flexible adaptation options: With the VARIO MOVE series of high-lift transport robots from ek robotics, MOBILE ROBOTS decisively supports the optimization of your intralogistic processes and goods transports.

As one of the leading manufacturers of automated guided vehicles (AGVs), ek robotics ensures greater efficiency, higher deadline accuracy and less transport damage in your intralogistics. As the leading integrator for autonomous mobile robotics, we at MOBILE ROBOTS are including the modular AMR series VARIO MOVE of our new partner in our portfolio, which is convincing in a wide range of industries.

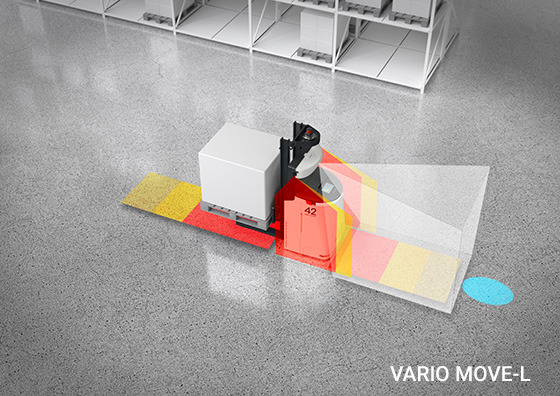

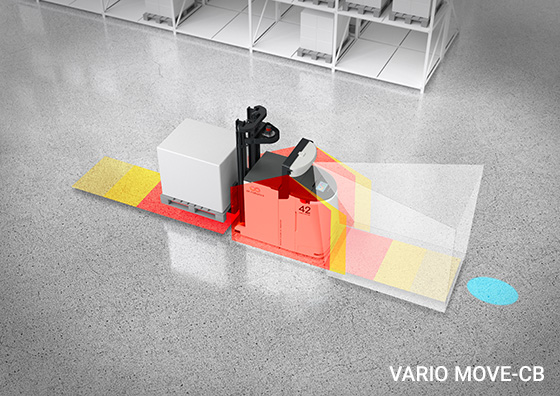

Individually adaptable, the VARIO MOVE concept allows maximum flexibility in device design and navigation. Due to its modular and maintenance-friendly design as well as its practically high availability, the VARIO MOVE represents the next evolutionary stage of transport robots: the industrial trucks, which consist of a drive unit with a modular interface, can be configured as desired despite standardized components.

This means they can be adapted to your transport tasks with different chassis and equipped with different load handling attachments. The VARIO MOVE "modular system" consists of five defined lift masts, with which a transfer height of up to five metres can be achieved, as well as a wide variety of load handlings - from load forks and attachments to roller conveyors or chain conveyors.