| Head-Slider BITO x1080 |

| Headline BITO < 768 px |

| Headline BITO |

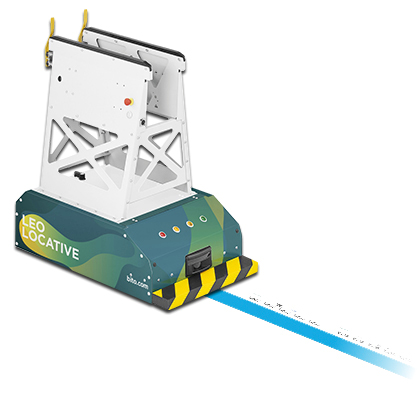

AUTONOMOUS SMALL PARTS & SLC TRANSPORT

| Text BITO 1 |

Simple intralogistics solution for automated transport of containers & cardboard boxes

In its basic version, BITO LEO Locative is a simple and flexible automated guided vehicle system without IT connection for intralogistics tasks up to a maximum payload of 20 kg. When connecting workstations in logistics and production areas, the decentralized LEO Locative, which is controlled without a host computer, is the perfect entry into the automation of your internal goods transport. The optically track-guided AGV receives its travel commands via optical markers on the floor and uses simply predefined routes to unerringly target BITO stations for fully automatic container pickup or transfer. WIFI is therefore not required.

The efficient automated guided vehicle system for small transports can be scaled as required for optimized goods distribution to over 500 internal destinations. For this purpose, the BITO standard system is supplemented with further components of a decentralized destination control at the stations. A tablet or barcode scanner can be used for destination entry. After manual input by the employee, the BITO station radios the information to the BITO transporter.

Like the user-oriented commissioning of the BITO LEO Locative, you simply carry out route changes independently if required. To do this, you position the pre-assembled BITO transfer stations and easily specify the transport path with a bonded track tape that can be removed at any time. You determine the stopping positions at the pick-up and drop-off points of the BITO LEO transporter by placing the corresponding floor markers parallel to the track tape.

| Text BITO 2 |

BITO LEO Locative: Your perfect start into automated goods transport

BITO LEO Locative with its comprehensive accessory box and pre-assembled BITO stations is the simplest automated guided vehicle system on the market and is ideally suited for smaller payloads, for example in the intralogistics of booming online retail. The automated guided vehicle system, which is mainly used for small parts, SLC transports and cardboard boxes, can be used across all industries. In addition to e-commerce, other practical scenarios include applications in electronics manufacturing, medical technology, mechanical engineering or automotive suppliers.

To realize applications with a high degree of automation, the track-guided BITO LEO Locative can also be connected to a goods management system for an optimized material flow. For centralized destination assignment, the LEO SmartBox interface enables integration with host computer (PDA) and warehouse management system.

Ready to go in 30 minutes: Automated container transport can be this easy - autonomous intralogistics without any programming.

| Bild BITO Spalte |

| Features, Facts & Benefits BITO |

Features, Facts & Benefits

Functional

• Easy access to automated intralogistics

for light containers and cartons

• Optically track-guided autonomous transport

of goods

• Connection of workstations through flexible,

decentralized destination control

for > 500 stations

Flexible

• No WIFI or host computer required

• Easily scalable / quick adaptations

• Navigation via tablet or floor scanner

Easy to operate

• Easy, self-contained setup

• Simple commissioning

• Fast operational readiness, no training required

• User-friendly operation

System integrable

• Optional WMS connection feature

Economical & efficient

• Short payback time

| Techn. Datenüberblick BITO |

Technical Specifications *

• Max. load capacity: 20 kg

• Dimensions (LxWxH): 820 x 500 x 921 mm

• Deadweight: 42 kg

• Power: 40W (DC)

• Voltage: 24V

• Noise emission: < 60 db

• Protection class: IP21

• Temp. operating environment: 5° C to 45° C

• Floor levelness (slope/incline): < 2%

• Color underground: no restriction

• Speed: max. 2.5 km/h (0.7 m/s)

• Power supply: accumulator

• Battery run time: 8 - 12 hrs.,

depending on load conditions

• Battery charging time: 6 - 8 hrs. (charger)

• Communication: optical track tape /

ground scanner

For further data see data sheet (below).

* correspond to manufacturer's specifications;

subject to change & errors excepted.

| Downloads Unterlagen BITO |

Further Information

| Button > Kontakt |

| Headline Bilder-Galerie BITO |

Click & Slide:

Impressions of BITO LEO Locative

| Bilder-Galerie BITO |

| Headline BITO Zubehör-Slider |

Optional Equipment & Accessories for BITO LEO Locative

| Zubehör-Slider BITO |

| Button > Testinstallation |

| Branchen & Einsatzgebiete BITO |

Typical Sectors & Industries for the Use of the Track-Guided BITO LEO Locative

• Automotive

• E-Commerce

• Mechanical Engineering

• Medical Technology

• Plastics Technology

• Electronics Manufacturing

| Call-to BITO bottom |

BRING AUTOMATED INTRALOGISTICS TO YOUR COMPANY

CONTACT US!

Make an appointment now to plan your autonomous intralogistics with MOBILE ROBOTS and let us talk about a customized integration of

BITO LEO Locative in your production.