| Head-Video rexroth ActiveShuttle |

| Headline rexroth ActiveShuttle < 768 px |

| Headline rexroth ActiveShuttle |

AUTONOMOUS SMALL PARTS & SLC TRANSPORT

| Text rexroth ActiveShuttle 1 |

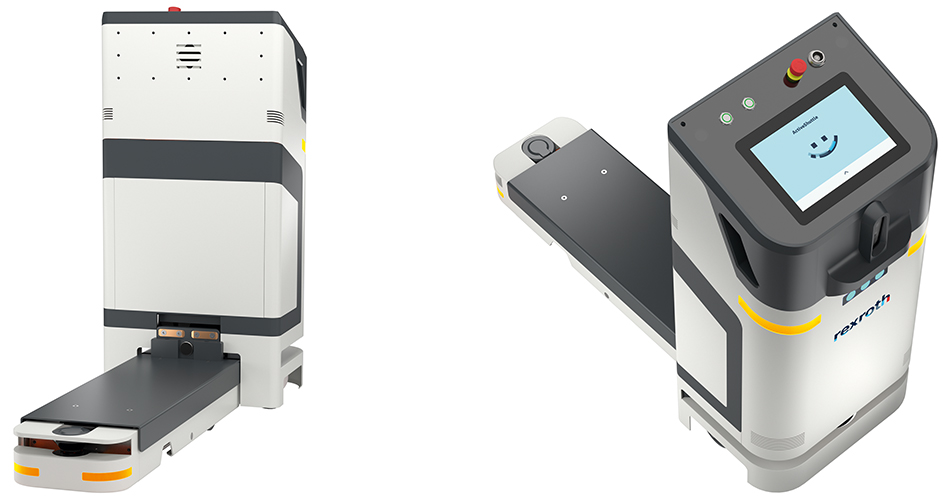

Autonomous production logistics next level: Rexroth ActiveShuttle

The flow of materials in modern production plants is complex, demand locations are diverse and distances are sometimes long. More and more individualized products, greater component diversity, simultaneously fluctuating production numbers - the competitive pressure of production facilities is increasing.

In this context, autonomous transport systems create the necessary flexibility and transparency in your intralogistics. Here, Bosch Rexroth sets a new standard with the ActiveShuttle: the system ensures the robust and efficient transport of loads up to 260 kilograms - fully automatically controlled.

Thanks to the ActiveShuttle Management System (AMS), manual material transports are finally a thing of the past, because thanks to robust and reliable laser navigation and 3D obstacle detection, the ActiveShuttle can move freely around the factory without adapting your factory infrastructure and automate your material and goods flow unhindered.

In practical use, compatible floor rollers with a base area of 600 x 400 mm or 400 x 400 mm are autonomously driven underneath and easily lifted with the integrated lifting platform. These floor rollers can be equipped with a variety of load carriers: transport small load carriers (SLC), blister packs or other containers. As soon as a transport order has been assigned to an available ActiveShuttle via the AMS, the autonomous mobile robot drives to its destination and deposits its goods automatically.

| Video rexroth ActiveShuttle (OnSite) |

| Text rexroth ActiveShuttle 2 |

With MOBILE ROBOTS and Rexroth ActiveShuttle plug & go to Factory 4.0

The ActiveShuttle driverless transport system enables you to enter the factory of the future today: It can be implemented quickly without adapting your existing factory infrastructure, it is intuitive to operate, fully networked and safe to use. Create transparent and efficient internal processes in your intralogistics with the ActiveShuttle!

Infrastructure adjustments are not necessary thanks to the reliable laser navigation of the plug & go integrated autonomous mobile robot. If several ActiveShuttles are implemented, the AMR communicate wirelessly and inform each other about changing environmental details in order to be able to react appropriately to bottlenecks in advance. The ActiveShuttle fleet immediately detects any changes in the production environment and automatically updates the reference map.

You can feed in orders manually, but also fully automatically thanks to existing standard interfaces. With the ActiveShuttle Management System (AMS), a variety of supply principles can be realized - from cyclical transports to demand-oriented material supply. Transport requirements, prioritisation and optimal distribution of pending transport orders to the AMR fleet are assigned to the respective available robots via order management.

The robust design and the use of proven navigation and sensor technologies guarantee high reliability and safety in dynamic production environments. The safety concept with integrated obstacle management, designed together with the German Social Accident Insurance (DGUV), ensures safe 24/7 continuous operation in mixed mode with man and machine. Safety laser scanners and stereo cameras record the surroundings in 3D and enable timely braking and safe passing of static objects or sudden obstacles in the travel path.

By using the ActiveShuttle now, you too can reduce space and material, streamline your value chain and significantly reduce processing times! It has never been easier to automate your flow of goods and materials.

| Bild rexroth ActiveShuttle Spalte |

| Features, Facts & Benefits rexroth ActiveShuttle |

Features, Facts & Benefits

Easy to integrate

• No adaptation of existing infrastructure

• Standard interfaces for the connection

of third-party systems

Collaborative & secure

• Secure collaboration with people

• Avoidance of static & moving obstacles

in busy environments

• Meets relevant safety standards

Flexible

• Easy adaptation of the AMR setup as a result

of process changes

• Reduction of space & material through

demand-oriented supply

Easy to operate

• Simple set-up & quick deployment

• User-oriented, intuitive operation

• Real-time monitoring of missions with

mobile devices

Robust & transparent

• Designed for 24/7 use in mixed operation

with man & machine

• Possibility of integration in ERP / WMS

• Live display of material movements

Scalable

• Simple, centralized fleet configuration

• Harmonized AMR coordination for efficient

traffic flow

Economical & efficient

• Higher productivity through fully automated

material transport and reduction of manual

handling steps

• Reduced workload for employees

• Efficient order management

• Bottleneck avoidance in the intralogistical

material flow

• Average amortisation: two years

| Techn. Datenüberblick rexroth ActiveShuttle |

Basic Technical Data ActiveShuttle *

• Max. lifting platform load: 260 kg

• Power supply: Li-Ion, 48 V, 17 Ah

• Battery charging time:

(20 - 100%): 90 min.

• Dimensions: 1,015 x 405 x 900 mm

(LxWxH)

• Lifting platform: 612 x 235 mm (LxW)

• Load dimension:

max. 600 x 400 x 1,200 mm (LxWxH)

• Lifting height: 118/135 mm (min/max)

• Ground clearance: 14 mm

• Dead weight: 70 kg

• Travel speed: max. 1.0 m/s

• Position accuracy: < 100 mm regular,

10 mm by support of opt. track guidance

• Safety: laser scanner type 3, SIL2,

Performance Level d (front/rear);

inductive safety scanner

(floor roll detection); 2 stereo cameras;

acoustic & visual signalling

• Communication: WIFI,

fully integrable with ERP / WMS

* correspond to manufacturer's specifications;

subject to change & errors excepted.

| Downloads Unterlagen rexroth ActiveShuttle |

Further Information

| Button > Kontakt |

| Headline Bilder-Galerie rexroth ActiveShuttle |

Click & Slide: Impressions of the Rexroth ActiveShuttle

| Bilder-Galerie rexroth ActiveShuttle |

| Button > Testinstallation |

| Branchen & Einsatzgebiete rexroth ActiveShuttle |

Typical Sectors & Industries for the Use of Rexroth ActiveShuttle

• Automotive Industry

• Mechanical Engineering

• E-Commerce

• Electronics

• Consumer Goods

• Medical Technology

| Call-to-Action rexroth ActiveShuttle |

BRING AUTOMATED INTRALOGISTICS TO YOUR COMPANY

CONTACT US!

Make an appointment now to plan your autonomous intralogistics with MOBILE ROBOTS and let us talk about a customized integration of the

small-load AMR Rexroth ActiveShuttle in your company